9 min read

5 Do's and Don'ts of Installing Electric Underfloor Heating

When it comes to building or even renovating, you only want to do it once, or it becomes a very costly exercise. And while most homeowners like to...

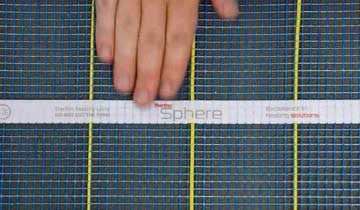

With the colder months approaching, many of us will be planning to turn the heating on or looking at new ways of heating our rooms cost effectively. Throughout 2022 we’ve seen a big rise in the number of enquiries for electric underfloor heating from homeowners who are going to take on the installation of the system.

So, for the DIYers out there who are researching electric underfloor heating installation or tradespeople who are new to it, this one is for you.

Create your plan!

You can never over plan especially when it comes to installing an electric underfloor heating system. It’s best to have all your requirements outlined before starting. This helps to minimise the likelihood of any errors or the need to completely start again.

Key questions to answer include:

The questions above are only a few examples but we’ve covered all of the ‘ins and outs’ in detail in another blog ‘What you need to know before installing electric underfloor heating’ which provides you with a useful checklist and guide.

Check the electrical circuit is suitable

An electric underfloor heating system can use a large amount of current so check the total load of the electric underfloor heating does not exceed the total load capacity of the electrical circuit.

A 10A system should be connected to the mains supply with a 16A thermostat and a 13A fused spur. The power supply should also be protected by a 30mA RCD and there should be capacity for the extra load demand of the electric underfloor heating back at the MCB in the consumer unit.

In addition, if the load of the electric underfloor heating circuit exceeds the maximum load of the thermostat (16A), but you want to control it from a single thermostat, then you must install a suitably rated contactor/snubber. It is worth asking a Part P registered electrician to check this as well as to make the final connections of your underfloor heating to the mains.

The calculation to use is:

(Heated area (m2) x Wattage of mat per m2(W)) / 230 = Load (A)

Consider a heat loss calculation

When deciding what heating output you need, it’s advisable to get a heat loss calculation. If you don’t install the correctly sized system, it will result in inefficiencies that could include a longer time for the room to reach the desired temperature and the system costing more to run.

By completing a heat loss calculation for the space, you want to heat, you’ll know the correct sized system required to heat to your desired room temperature. This may even result in fewer cables and less power required to stay toasty, which is better for your bank account and for the environment.

Test 3 times!

It can be extremely frustrating to have to remove a section of the floor covering to fix an issue that would have been prevented by testing the system during installation.

We always recommend testing the electric underfloor heating system three times.

The results for these three tests are usually required by most electric underfloor heating manufacturers as part of the warranty registration of the system.

Ask your electrician

Electric underfloor heating can be installed by any competent person. However, the final connection to the mains must be completed by a Part P registered electrician.

But before turning the system on, you must wait for tile adhesive and/or self-levelling compound to fully cure (depending on what system is installed and the build-up used). This can take between 7-14 days, but we recommend checking the manufacturer’s guidelines to make sure.

A typical commissioning process looks like this:

Don’t ever cut the heating cable!

We often get asked “I’ve got too much heating cable. Can I cut the end off?” The simple answer is no! Here’s why.

Unlike a regular electric cable, electric underfloor heating cable gets hot because it resists the flow of electricity. It’s this resistance which creates the heat.

Electric underfloor heating cables are designed at an exact resistance in order to emit the right amount of heat along the entire length. So, if you cut the excess cable off you reduce the resistance and the wire will overheat causing damage.

Cutting the heating cable also invalidates your warranty. With ThermoSphere underfloor heating, If you or an installer accidentally damage the cable we have few options to help you out.

If the installer is registered to ThermoSphere CONNECT we’ll send a free replacement – provided that the floor finish has not yet been laid. We also have engineers that can come out to fix the cable and issue a warranty on their repair.

Don’t run electric underfloor heating like a central heating system

Radiators create heat through convection by warming the cool air at the bottom of the radiator, which warms as it passes over the fins, rises to the ceiling and cools again. Radiators need water at a temperature of between 65°C degrees and 85°C degrees to be pumped through which takes more energy and therefore less energy efficient.

Electric underfloor heating generates radiant heat and in effect turns the floor into a large radiator. The heat gently rises upwards and creates a comfortable level of warmth which is evenly distributed throughout which means no cold spots in the room.

Electric underfloor heating is more efficient than radiators because it runs at much lower temperature. You can run electric underfloor heating at a maximum of 27°C for soft floor finishes such as wood, carpet or vinyl. But, if you are installing a tile or stone floor, you can increase the temperature a little to around 29°C.

Electric underfloor heating works differently to radiators and doesn’t need to be run at such high temperatures. The radiant heating principle means that the whole floor is effectively used as a low surface temperature radiator and because you’ve got such a large, heated surface the running temperature can be much lower – often around 21-23°C. Then use a setback temperature of between 16°C and 18°C for the times that you would effectively like your heating off.

It's important to remember that you can save on both energy and cost by reducing your heating temperature by just 1°C.

Don’t try and save time by cutting corners

Over the years, we’ve seen it all. From coils of extra cable hidden behind a bath panel that have overheated and melted together, to wiring the heating cable directly into the mains without installing a thermostat and temperature sensor.

For the best results, always follow the instructions. If you get stuck, we have a huge resource of helpful installation guides on our website and on our YouTube channel that have been created to help make installing your electric underfloor heating system a doddle.

Don’t put cost over quality

With electric underfloor heating rising in popularity, we’ve seen an increase in the number of electric underfloor heating systems being sold. From eBay to Amazon there are so many systems to choose from. They all vary on price and quality. But what is best for you?

The quality of the heating cable is important. Some offer standard heating cable and others, just like us, offer better quality which protects the integrity of your installation. For example, all our heating cable features a twisted construction which means that there are far lower stresses on the conductors and therefore lower frisk of damage.

Warranty is another key consideration. There’s a real mixed bag, but ideally you want a lifetime warranty with the system and one that stays with the home rather than the individual. Should you come to sell your property, your buyers will be delighted to hear that the electric underfloor heating system is still covered by a warranty. As always, we recommend that you check the small print of any warranty.

If you have any questions about your electric underfloor heating project, please contact our team who are always on hand with helpful advice that can save you both time and money.

9 min read

When it comes to building or even renovating, you only want to do it once, or it becomes a very costly exercise. And while most homeowners like to...

6 min read

Tiled floors are the most common floor finishes to have over electric underfloor heating and for good reason. Electric underfloor heating is more...

12 min read

Electric underfloor heating is a simple and effective heating system to install in both retrofit and new build projects. Any competent DIYer can do...