5 min read

How to run your electric underfloor heating system

With the colder months fast approaching, many homeowners will start to think about turning on their heating and some may even be getting new heating...

Underfloor heating is well-known for warming cold tile and stone floors, but it can also make a wooden floor finish feel a million dollars. So, if you are currently exploring all the options for a renovation project and you’re wanting a wooden floor finish, then this heating blog is a must read.

To help answer any questions you may have about using electric underfloor heating with a wooden floor finish, we’ll be covering the following:

• What type of wooden floor to consider

• The qualities to look out for when choosing a wooden floor finish

• The best electric underfloor heating system to use

• Typical floor build ups

• Installation tips

If you’d prefer to ask any questions directly, the team here as ThermoSphere HQ are always available. Just contact us by telephone or email.

If you are wanting to warm wooden floors, there are traditionally two types that will perform well. These are engineered wood flooring and solid timber flooring.

Engineered wood

Engineered wood is an incredibly popular floor finish. It’s man-made and has a plywood backing and a solid hardwood timber finish. Engineered wood works well with underfloor heating because the laminated structure helps the floor to effectively withstand the natural contraction and expansion (caused by moisture in the atmosphere) without impacting the efficiency of the system.

It's worth pointing out that, in some instances, cheaper engineered wood options tend to have a softer core which will absorb more moisture which can swell over time. This type of swelling may cause a failure of the floor finish such as bowing which will cost time and money to put right. So, before you part with your cash, we recommend consulting the flooring manufacturer to see if underfloor heating works well with their engineered flooring.

For the interior designer in you, engineered timber is available in a variety of sizes, patterns and grains which provides great flexibility in terms of the finished look and feel. Did you also know that engineered wood can be installed at any floor level. Board width is also important and for use with underfloor heating, a board width of 160mm is ideal.

Solid timber

Solid timber floors are made from natural hardwood which has been cut into boards after being treated. The quality of the solid timber is vital when using it with underfloor heating.

You’ll need a board with a low moisture content such as narrow kiln-dried boards to mitigate the risk of the floor warping or bowing. Like engineered wood, the higher the moisture content of the solid timber board, the higher the risk of potential floor damage. Even the temperature difference of the seasons can impact the floor. For example, natural solid timber floors can’t be used for basements as they are more susceptible to moisture related warping.

Conducting heat

When using underfloor heating with a wooden floor finish, the temperature of the floor surface should not exceed 27oC. You might be wondering where this number came from. It comes from historic research which explored the growth and shrinkage rates of timber floors. It was at 27oC that the expansion of the timber tested was deemed ‘invisible’ to the eye, and therefore the ideal temperature was discovered.

As mentioned previously in this article, even though this temperature is known industry-wide, contact the flooring manufacturer because there will be instances where the maximum temperature will vary.

Thickness of board

Both the thickness and density of the wooden floor can impact the performance of the underfloor heating system. Narrow boards often show less movement than wider boards and the rule of thumb is to try and source a board where the ratio of thickness to width should be in the range of 7 to 11. As an example, a board with a width of 160mm and a thickness of 16mm would give a ratio of 10, which is ideal!

In most instances, a foil electric underfloor heating system would be the ideal system to use. These systems are usually specified on projects where floating floor finishes are being installed such as wood, carpet or vinyl. They have been purposefully designed to not overheat softer floor finishes and are installed without needing to use adhesives.

Foil systems, such as ThermoSphere Foil or Warmup’s Foil Heater System (both with an output of 140W/m2), provide great thermal conductivity and fast heat up times because the heating cable is wrapped between two layers of foil which is a brilliant thermal conductor.

When assessing what foil system to specify, you’ll notice that they all look very similar. However, there are subtle differences which give both efficiency and practicality a healthy boost. These differences could include accessible cable loops for faster installation and if the heating mat is fully earthed straight of the box.

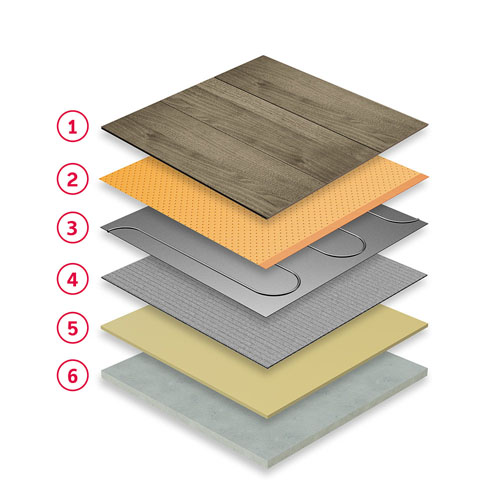

Typical build-up for concrete substrates (above)

1. Engineered timber 2. Cushioning overlay 3. Foil 4. Cushioning underlay 5. Uncoated insulation board 6. Concrete substrate

Height: 20.5mm (Excluding the substrate and layer 1)

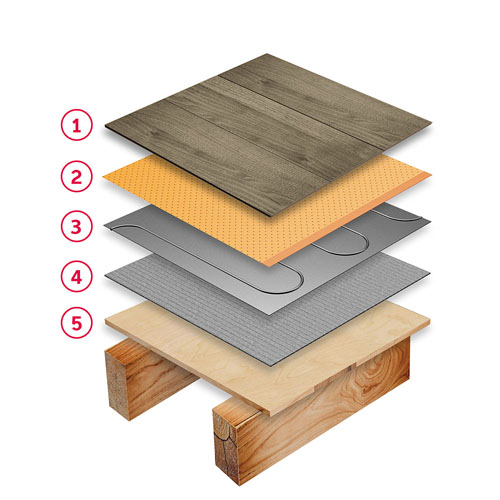

Typical build-up for timber substrates (above)

1. Engineered timber 2. Cushioning overlay 3. Foil 4. Cushioning underlay 5. Timber substrate.

Height: 10mm (Excluding the substrate and layer 1)

Be prepared and plan

Installing any underfloor heating system requires careful planning. A well-planned installation minimises the likelihood of errors and the need to potentially start again.

Key considerations include:

The output of the system (A foil system is usually 140W/m2).

What floor substrate you are installing on. This will inform you of the type of insulation board you need.

The position of the thermostat and the floor sensor.

For a more detailed guide, read ‘7 tips before buying electric underfloor heating’.

Test three times

This doesn’t just apply to an installation of a foil system, it’s a general rule. There are three tests to carry out during installation:

For further information on testing, read ‘How to test an electric underfloor heating system’.

Install two floor sensors

This is something we always recommend and for good reason. Should, for any reason, the floor sensor fail when using the underfloor heating system, the only way to fix it would be to take up part of the floor and install a new one or switch to air sensing mode. Using air sensing mode is not as efficient as measuring the temperature of the floor which means that the system can be on for longer and cost more to run. Also, measuring the floor temperature will help to ensure that the maximum floor temperature is not exceeded.

So, we recommend installing two floor sensors. One will be connected to the thermostat and the spare can easily be connected to the thermostat should the other fail.

Irregular areas

The foil will not always fit the spaces around irregular shapes which some permanent fixtures may have. In this case the foil should be cut into strips containing the cable and arranged to cover the area. Use a minimum cable spacing of 50mm and fix in place using aluminium tape.

Watch the ThermoSphere Foil installation video for a detailed step-by-step guide.

Don’t install without insulation board

Insulation board is often seen as a ‘nice-to-have' but it’s very much a ‘must-have’. Installations where insulation board hasn’t been used take longer to reach the desired temperature because almost half of the heat produced is lost through the subfloor. Insulation board has the potential to improve the efficiency of the system by up to 50% if installed correctly.

Thermal blocking is more common with wood, carpet and vinyl floor coverings. For example, if you have a wooden floor which has some slight discoloration in one area where a bean bag or thick rug used to be, then this is a sign that thermal blocking has occurred.

Thermal blocking occurs when airflow is restricted to the floor which blocks the heat from radiating from the floor to the room which causes overheating and results in damage to the floor. In fact, flat-bottomed furniture or any rug with a tog rating of 2.5 and above should not be placed over a heated floor. If you have permanent furniture, then we would recommend using bun feet or similar. If you want a rug in the room, a hessian rug with a low thermal resistance should be fine. However, please check with the manufacturer before parting with your hard-earned money.

If you have a question about anything covered in this heating blog or a more general question about ThermoSphere’s range of electric heating please contact one of the ThermoSphere team who will be happy to help.

5 min read

With the colder months fast approaching, many homeowners will start to think about turning on their heating and some may even be getting new heating...

5 min read

With the heating season just around the corner, and one of the busiest times of the year for any heating manufacturer, we thought it would be a good...

12 min read

It won’t be long before we start thinking about turning the heating on to combat the chill of the winter months. As the heating season fast...