6 min read

The best electric underfloor heating for tile and stone floors

When it comes to underfloor heating, it is much more common to heat tile or stone floors than wood, carpet or vinyl. So, you can imagine why one of...

Tiled floors are the most common floor finishes to have over electric underfloor heating and for good reason. Electric underfloor heating is more commonly found in bathrooms and kitchens which are most commonly tiled, but tiles are also great conductors of heat which means you’ll feel the warmth faster.

In this heating blog we’ll be focussing on how to effectively tile over an electric underfloor heating installation. We will be covering:

• Why choose tiles

• The best electric underfloor heating system for tiled floors

• Top installation tips

If you prefer to watch about tiling over electric underfloor heating, check out The complete guide on installing ThermoSphere Membrane & Jointless Cable - Electric underfloor heating system.

Tiles are a superb natural conductor of heat and help to make the heat transfer evenly and quickly throughout the room. This means that you are less likely to get cold spots in the room which you commonly get with other types of heating such as radiators.

Luxury tiles give a great feel to any room, and there’s lots of options out there. Porcelain and Ceramic tiles are the most popular types of floor tile and in many cases a more affordable compared to alternatives like stone floor tiles. Tile thickness has little impact on heat output, but sometimes thicker finishes (up to 20mm) can increase the heat up time whilst the heat transfers through, but it also holds the heat for longer. Most internal floor tiles are approximately 10mm – 12mm thick which is ideal for electric underfloor heating.

If Ceramic or Porcelain tiles are not to your taste and you feel the natural stone route is more for you, then here are some options to consider:

• Limestone: offers a great timeless finish.

• Marble: available in many different thicknesses, marble is a great conductor of heat.

• Slate: perfect for underfloor heating because it is one of the best conductors of heat in the natural stone category.

One of the main risks associated with heating tiled floors is cracking of the tile itself or the grouted joints. Reasons for this include temperature variations in the tile and/or substrate due to heating and cooling cycles and even by seasonal temperature changes.

Another risk is accidentally snagging the heating cable with a trowel when applying adhesive ready for the tile to be laid on. This will get flagged when you test the electric underfloor heating system during installation.

Early in the installation process, you must ensure that the subfloor that you are installing your underfloor heating on is level. This is important to ensure that the heat is distributed consistently and not affected by differing thicknesses of adhesive cover.

You can mitigate these risk factors by making sure you use a flexible cement-based tile adhesive and grout and that they make adequate provision for expansion and contraction (movement joints).

We’ll start by saying that either a heating and decoupling system (ThermoSphere Membrane) or a pre-spaced mesh mat system (ThermoSphere Mesh) are both great options for tiled floor finishes. But what are the differences?

Heating & decoupling

A heating and decoupling system is designed to prevent cracking, lifting and delamination of tiled floors caused by lateral movement. The decoupling layer allows the tiled surface to move independently from the subfloor. It has waterproofing properties too which makes it ideal for wet room projects.

There are multiple cable spacing options which allows you to choose the right output for the project. For example, using ThermoSphere Membrane, you can use a two-stud spacing for an output of 195W/m2 or a three-stud spacing for an output of 130W/m2.

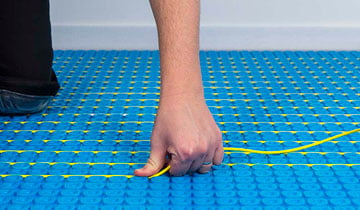

By using this system you also will help to protect the cable during installation because the heating cable is pressed in-between the studs mitigating risk of damage caused by a heavy hand using a trowel.

Mesh mat (heating mat) systems

A pre-spaced mesh system has a heating cable already attached to a mesh mat at regular intervals and there are a variety of outputs available. The higher the wattage, the faster the heat-up time. For example, 200W/m2 is perfect for high demand rooms like conservatories. 150W/m2 is a great primary heat source for well insulated rooms and 100W/m2 is usually for floor warming only.

When spreading the flexile tile adhesive (or levelling compound) over the mesh mat there is a higher risk of damaging the heating cable with the trowel if the system you have chosen is installed wire side up. Any damage could cause the underfloor heating system to fail. This is why we recommend mesh mat systems that are installed wire side down so the mesh protects the heating cable from accidental damage.

Ensure complete coverage

When installing the ThermoSphere Mesh or Membrane systems, you must ensure that the heating cable is completely covered in tile adhesive. The adhesive layer acts as a 'heat sink' to conduct heat away from the cables and into the floor and room. Some installers like to cover the cable with a layer of self-levelling compound before tiling which is fine to do. By doing this you ensure there are no air gaps, which protects the cable and you get a nice level surface to tile on.

Always specify insulation board

Leaving insulation off the floor build-up will mean that the room will take longer to reach the desired temperature and that means it will cost more money to run and energy will be wasted. Including insulation board, reduces downward heat loss through the subfloor and instead most of the heat will be heating the floor above. This can improve the efficiency of the electric underfloor heating system by up to 50%!

If you’re installing in a wet room

We would recommend not to exceed 150W/m2 and install the electric underfloor heating system at least 300mm away from the wet room drain so that the drainage trap doesn’t dry out.

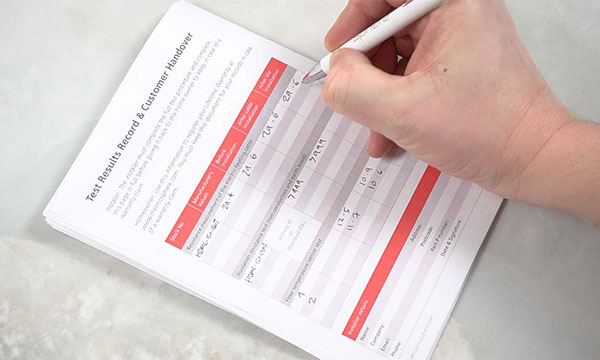

Don’t forget to test!

This applies to all electric underfloor heating installations no matter the floor finish. But it is worth adding it as a gentle reminder because it’s frustrating to have to remove a tile to fix an issue that would have been prevented by testing the system.

There are three tests to carry out. These are:

The results for these three tests are usually required by most electric underfloor heating manufacturers as part of registering the system for its warranty.

For further information on testing electric underfloor heating, read How to test an electric underfloor heating system.

If you have a question about anything covered in this article, please contact one of the ThermoSphere team who will be happy to help.

6 min read

When it comes to underfloor heating, it is much more common to heat tile or stone floors than wood, carpet or vinyl. So, you can imagine why one of...

8 min read

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...

6 min read

Kitchens are usually the most used living spaces in any home and are often not just for cooking but for entertaining in too. For the ‘heart of the...