3 min read

Why choose the Ultimate heating cable

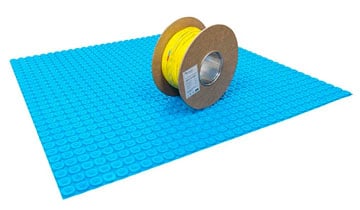

At ThermoSphere we’re excited to launch the new improved version of our underfloor Membrane Heating Cable. We’ve been working hard to introduce...

For 25 years we’ve used our expertise to drive innovation forward, and our new ThermoSphere Ultimate Heating Cable is the newest instalment in a long line of technical advances. To find out more about the product, we caught up with, Samuel Hills, Product and Innovation Lead here at ThermoSphere, who heads up the team responsible for the heating cable redesign.

The short answer is heating cables without bulky cold tail joints. Though, the long answer is more interesting and has lots of benefits for installers.

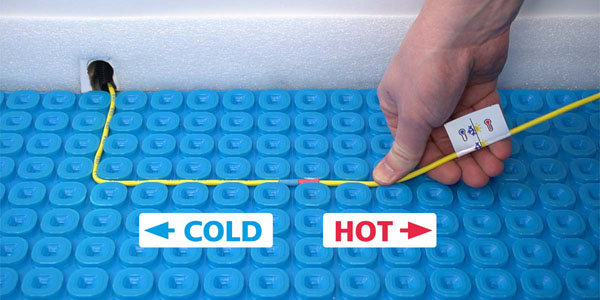

All underfloor heating cables have to connect to the thermostat, and the cable that does that is called the “cold tail”. On almost all electric underfloor heating cables, the cold tail connects to the hot cable with a joint made during the secondary manufacturing process. In other words, two cables are made – a hot and cold – and then later they are soldered or crimped together, making a joint, and heat shrink wrapped for protection. This process results in a bulky joint that’s typically three times larger than the heating cable, at around 12mm, and most cold tail cables are much thicker than the hot cable too – ThermoSphere Ultimate is 4mm, not 10mm like others.

We know the bulky joint and thick cold tail causes many problems for installers, who need to have a flush surface ready for tiling. Thick cables and bulky joints mean that for installers to achieve a flush surface, they have to resort to workarounds, like cutting the membrane and insulation, or chasing out concrete or wood to make small cavities in the floor. This is a primary cause of damage to the cables during installation and it makes installation much more complex and time consuming.

So, we got rid of the traditional bulky cold tail joints by creating them in-line during the manufacturing process. Now there’s just one cable that’s 4mm in diameter end-to-end.

By getting rid of the traditional joints we could get rid of the problems they create, which drastically transforms the installation process. Bulky joints mean cutting insulation, chasing out concrete or wood floor, and cutting the membrane, which also ruins the integrity of the waterproofing layer. Using in-line joint technology means all of those issues are gone and installers can provide quality workmanship, quicker.

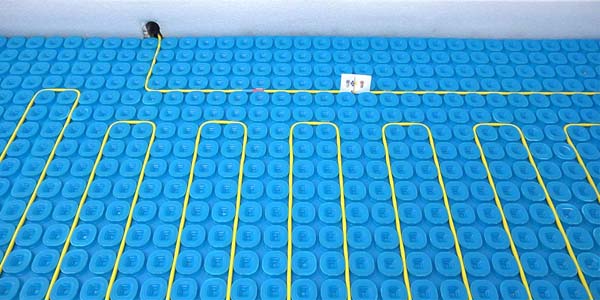

Normally installation time depends on the size of the project and how complex it is, which typically comes from the cutting required for the joints. If your project ends up being a multi-cable project, then you also need to cut full channels for the lengths of the cold tail to reach the wall too.

With ThermoSphere Ultimate, we got rid of all the complexity. Now the installation time just depends on the size of the project.

Once the membrane mat is down, installing the cable is a one-step process. You press it into the mat, with the right spacing, and you’re done. It’s automatically flush ready for tiling and the temperature sensors. The same goes for multi-cable projects. If you have to run extra cold tails, you just press them in as you would the rest of the cable.

We’ve released four new cable lengths (42m, 55m, 90m, and 175m meters) to more readily fit different sizes of installation. This also speeds up the installation process which means other trades can get on site sooner, customers are happier as their project gets finished quicker and installers can deliver more projects.

Both are equally as reliable as one another. But a primary point of failure resulting from the installation process is the traditional hot-to-cold joint. This is because of the workarounds installers have to make to accommodate the bulk of the joint and the thicker cold tail.

In some installations the joints get nicks from Stanley blades used to cut into the membranes and those nicks mean the cables will automatically short when turned on. In some installations the cuts and channels create air gaps, which leads to the cables overheating months or years down the line. In turn this results in customers coming back to installers with complaints.

By designing out the potential for damage, installers get the peace of mind that any job is done and dusted. It saves them the time and cost of having to return to a job, which can enhance the installers reputation with customers too.

Homeowners that choose ThermoSphere Ultimate won’t have to worry about overheating because of the air gaps around the bulky joints or shorts coming from nicks in the cable. This means when they get new underfloor heating, they can be sure that its quality and long-lasting from day one. In fact, ThermoSphere has a lifetime warranty for its heating cable, as long as it’s not damaged during installation, and as long as the flooring stays down.

For more information head to the dedicated ThermoSphere Ultimate page.

3 min read

At ThermoSphere we’re excited to launch the new improved version of our underfloor Membrane Heating Cable. We’ve been working hard to introduce...

2 min read

As a leading British manufacturer of electric heating, ThermoSphere are not only committed to leading the charge in changing the way homes are...

2 min read

70% of faults with an electric underfloor heating installation occur around the cold tail joint of the heating cable. This not only causes a headache...