14 min read

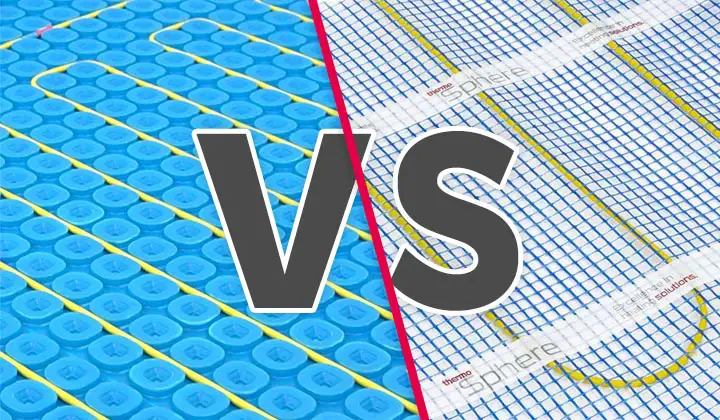

Electric underfloor heating: Mesh mat vs heating & decoupling system

Deciding what is the best electric heating system to use for your project can often be confusing especially when many of them can effectively heat...

So, you’ve completed your research on electric underfloor heating and have decided that it’s the perfect fit for your project. But, with so much choice out there, trying to work out which electric underfloor heating system is best suited for the task at hand can often be a little daunting, especially for ‘first timers’.

In this heating blog, we walk you through everything you need to know to choose the right underfloor heating system. We’ll be covering:

When researching electric underfloor heating, you’ll more than likely come across four common systems. These are the traditional pre-spaced mesh mat, heating and decoupling, foil, and in-screed systems. You’ll find that the names of these types of electric underfloor heating systems will vary depending on the brand you go for, but they all do the same thing, however some do it better than others.

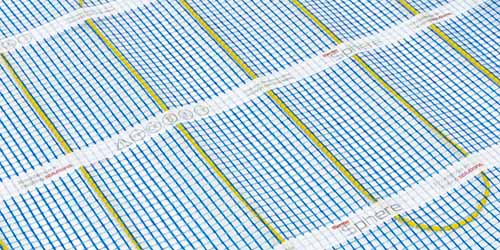

This type of electric underfloor heating system uses a length of heating cable attached to a mesh mat at regular intervals and is the more traditional system compared to heating and decoupling as well as foil systems. Good quality mesh systems have a self-adhesive layer so you can just roll out and stick down on the insulation board. Ideally, you want to use a mesh system that is stuck wire-side-down, so that the heating cable is protected from a heavy hand using a trowel to spread tile adhesive. One nick of the heating cable could make the whole system fail even before the floor covering is laid.

There are a variety of outputs available with this type of electric underfloor heating system. For example, ThermoSphere Mesh (manufactured in Great Britain), is available in outputs of:

100W/m2 - Ideal for larger, well-insulated and commonly used rooms that require warmth for most of the day.

150W/m2 – Heats up faster than a 100W/m2 system and is the most common option that maintains an optimum temperature in rooms that have a small amount of heat loss.

200W/m2 – Has the fastest heat up time and is the ideal choice for maintaining comfortable temperatures in higher heat loss rooms such as conservatories, or for rooms that occasionally require short bursts of heat.

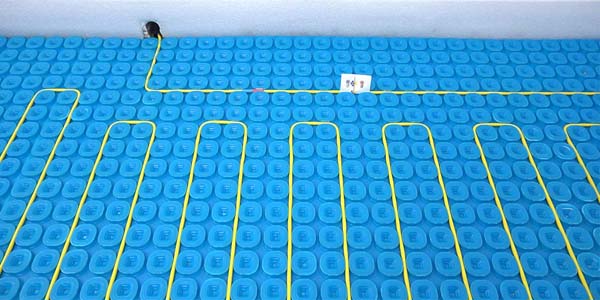

Best to use with: Tile or stone floor finishes

A heating and decoupling system is a more modern innovation compared to a mesh mat system. There are two core components. A decoupling membrane mat and a reel of heating cable. The decoupling membrane is designed to prevent cracking, lifting and delamination of tile and stone floors. It allows the floor finish to move independently from the subfloor and reduces any risk of damage caused by expansion and contraction. You’ll find that different brands of membrane mats have different shaped studs or dimples, however they all are designed to hold the cable securely in place.

A heating and decoupling system allows for different heating outputs by changing the spacing between the cable. For example, using ThermoSphere Membrane, you can use a two-stud spacing for an output of 195W/m2 (ideal for wet rooms) and a three-stud spacing for an output of 130W/m2 (great for well-insulated buildings).

Additional benefits of this type of electric underfloor heating system include cable protection because the heating cable is pressed in-between the studs reducing the risk of catching it with a trowel when spreading tile adhesive over. The decoupling membrane also provides a waterproofing layer which makes it perfect for wet room projects.

Best to use with: Tile or stone floor finishes (especially suited to wet room projects)

A foil electric underfloor heating system is designed to be used with floating floor finishes which includes wood, carpet or vinyl. As well as having a specific output, foil electric underfloor heating systems are purposefully designed to not overheat soft floor finishes and are installed without having to use adhesives. These systems provide great thermal conductivity and fast heat up times because the heating cable is wrapped by two layers of foil which is an ideal thermal conductor.

These systems may look similar but there are subtle differences which make the efficiency and practicality of different systems better than others. This could include exposed cable loops for faster installation and if the system comes fully earthed straight out of the box.

We have written specific articles for different soft floor finishes which will help if you have already decided what floor finish you will be laying.

The best underfloor heating for wooden floors

Can you use electric underfloor heating under carpet?

Best Underfloor Heating for Vinyl

Best to use with: Wood, Carpet or Vinyl

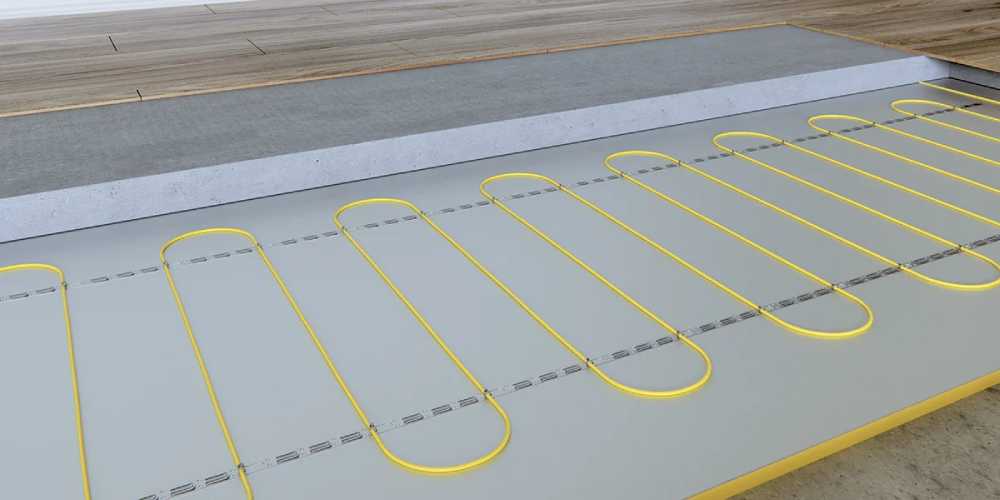

In-screed systems are more readily used in new build or extension projects because the heating cable can easily be installed in the screed layer during the building phase of the project. In-screed electric heating systems take longer to install compared with electric underfloor heating mats, so we would recommend using a pre-spaced fixing profile for an easier and more secure cable installation. The heating output per m2 can be adjusted by varying the cable spacing to achieve the desired heating output. Installing perimeter foam is also a wise decision because it allows the screed to expand and contract when heated. Not allowing for this could result in a breakage in the screed.

In-screed underfloor heating systems are ideal for rooms that are in almost constant use as they have longer heat up and cool down times. They provide a great opportunity to take advantage of low-cost energy tariffs like Economy 7 because of the slower heat up and cool down time.

Best to use with: Any floor finish

Electric underfloor heating is mostly used in retrofit projects or for smaller floor areas. This is because there is minimal impact on floor height and a faster installation time (depending on the size of the room). However, it’s becoming more popular in new build projects due to its superior energy efficiency, low capital cost and ease of installation.

On average an electric underfloor heating system will take 20-30 minutes to heat the room to the desired temperature as long as the system has been installed correctly and with insulation boards.

The higher the wattage the faster the heat up time. So, for bathroom projects we would recommend an output of 150Wm2 and for conservatories we would suggest 200W/m2. The reason for the higher wattage for conservatories is because they are more prone to heat loss.

Electric underfloor heating can be used as a primary heat source!

It’s a myth that electric heating can’t be used as a primary source of heat for new build or retrofit projects.

If you are considering using electric underfloor heating as a primary heat source, we would recommend getting a heat loss calculation. This will tell you what the heating output of the system should be to effectively heat the space.

Electric underfloor heating uses a large amount of current and therefore we would advise consulting a professional electrician to check that the total load of the system does not exceed the total load of the electrical circuit.

How much electric heating do you need?

Use this calculation to work it out:

Floor Area (m2) – Area taken up by fixed units (m2) = Total Underfloor Heating (m2)

What are fixed units?

As an example, the fixed units in a bathroom are the bathtub, sink and toilet. Fixed units along with any type of flat-bottomed furniture such as bookcases will restrict airflow to the floor which causes ‘thermal blocking’. This can result in the heating cable overheating which will damage the floor covering above. Therefore, always calculate for fixed units and flat-bottomed furniture when working out how much electric underfloor heating you need.

Opt for smarter heating control

Whether it’s smart control for electric radiators or for your electric underfloor heating, there are a wide range of options available. In fact, smart thermostats have the most potential of any thermostat to help you to reduce the running cost of your electric underfloor heating system. We cover smart thermostats in detail in ‘Do smart thermostats save you money?’

For further detail on electric underfloor heating such as running costs, installation top tips and answers to the most common questions, it can all be found on our heating blog.

If you have a question about anything covered in this article, please contact one of the ThermoSphere team who will be happy to help.

14 min read

Deciding what is the best electric heating system to use for your project can often be confusing especially when many of them can effectively heat...

10 min read

When deciding what type of system is best to heat tiled floors, we often get asked why we suggest ThermoSphere Ultimate over ThermoSphere Mesh and...

9 min read

If you are researching the feasibility of electric underfloor heating for your home, you may see a lot of examples that simply talk about underfloor...